New business 1960–1989

The 1960s through to the 1980s were marked by transformation at Bosch, turning it into a diversified group with self-managed divisions, a global company, and the market leader in automotive electronics.

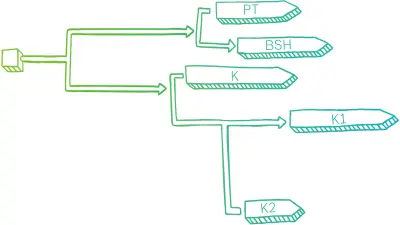

New structure — divisions are formed

Between 1950 and 1960, the number of Bosch associates increased from 15,000 to 70,000. The centralized structure of a medium-sized enterprise no longer sufficed, and so during the 1960s the business fields gradually became more independent, starting with the Power Tools division. During this time of economic boom and full employment, Bosch made acquisitions in other sectors and thousands of associates were retrained to manufacture automotive electrics.

From hydraulics to packaging

Even if the automotive industry in the most important market for Bosch at that time, western Europe, was booming, the diversification drive into other sectors was still important. After moving into mobile hydraulics, medical electronics, and radio technology during the 1950s, Bosch bought into a packaging machinery company in 1963 and expanded its activities with further acquisitions to form the Packaging Technology division.

The founder’s legacy — the Robert Bosch Stiftung

Research, development, and acquisition — with the power of innovation

Bosch pooled its research and development resources in a new research center in 1968. This combined effort was needed to germinate the ideas that Bosch later turned into the innovative products that gave it the competitive edge. From the mid-1960s, the company’s own research institutes also focused on special projects, such as integrated circuits.

The Jetronic

Electronics take over

In 1959, Bosch started to develop an electronically controlled gasoline injection system. The Jetronic was the first system of its kind in the world to go into mass production in 1967. It was first used in the U.S. versions of the Volkswagen 1600 LE and TLE. Thanks to Jetronic, the VW 1600 was able to satisfy the comparatively strict environmental regulations that had been introduced in the U.S. State of California.

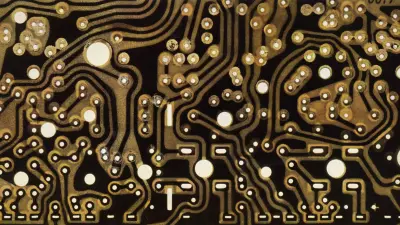

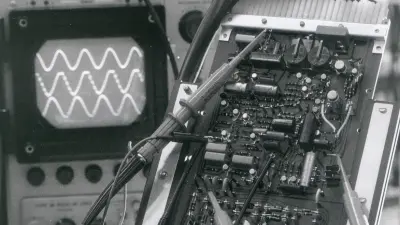

Photo: Board of a Jetronic electronic control unit for gasoline injection in the electronics laboratory at Schwieberdingen Technical Center near Stuttgart (1970)

Semiconductors and the computerized car — electronics at Bosch

The determination of the researchers and managers to turn electronics into a linchpin of the company started to pay off from the 1970s, and that originally uncharted territory has shaped the entire company’s success to this day. A prime example of this is the ABS antilock braking system launched in 1978, which Bosch turned into a technical standard in automotive engineering thanks to its expertise in digital electronics.

Thinking global — a new start in the U.S. and Asia

In the United States, the world’s largest economy, it took till 1983 for Bosch to get the full usage rights reinstated for its own brand. This freed the way for the company to regain its former sales success. In Asia, Bosch established its presence in a special way. It manufactured high-quality goods, such as photographic and video technology, more cost-efficiently in countries such as Malaysia. It also formed joint ventures in key markets such as Japan. Bosch started manufacturing electronic gasoline injection there in 1973 and the ABS antilock braking system in 1984.

The lambda sensor

Sensitive sniffers

In 1969, Bosch experts started developing a sensor for measuring exhaust gas, which established itself within a good decade following initial teething troubles. Nowadays, environmentally friendly combustion engines are no longer conceivable without the lambda sensor, which went into production in 1976. This Bosch innovation was the prerequisite for exhaust treatment using three-way catalytic converters. The lambda sensor measures the oxygen content in the exhaust gas upstream of the catalytic converter. This value, which constantly fluctuates dramatically according to the driving situation, is used by the electronic control of the injection system to adjust the composition of the gasoline-air mixture. The system’s accuracy ensures complete combustion, which enables the catalytic converter to optimally clean the exhaust gases. This can reduce harmful emissions by up to 90 percent.

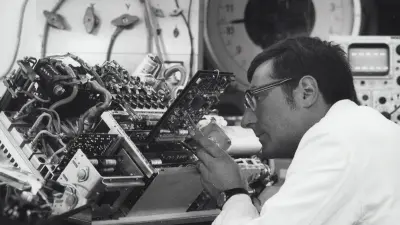

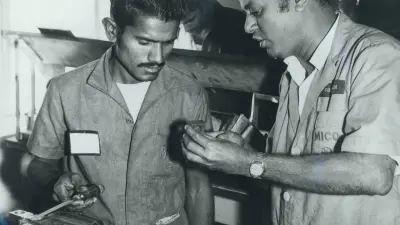

Photo: Function testing of lambda sensor prototypes in Schwieberdingen Technical Center (1975)

Telecommunications — a new focus

At the start of the 1980s, Bosch ventured into telecommunications and started constructing technology for space satellites and cell phones and implementing public and private telecommunications networks. After two successful decades of this sector generating up to 25 percent of the company’s sales, unfavorable developments prompted Bosch to withdraw from several segments. The Security Systems division continued in business and remains successful to this day.